What is Wheel Peening Process?

Wheel Peening is an proven process designed to enhance the fatigue strength of components which are subjected fluctuating load. Wheel Peening strengthens lighter components which, optimized for weight and cost/benefit, can be loaded up to the limits of their properties.

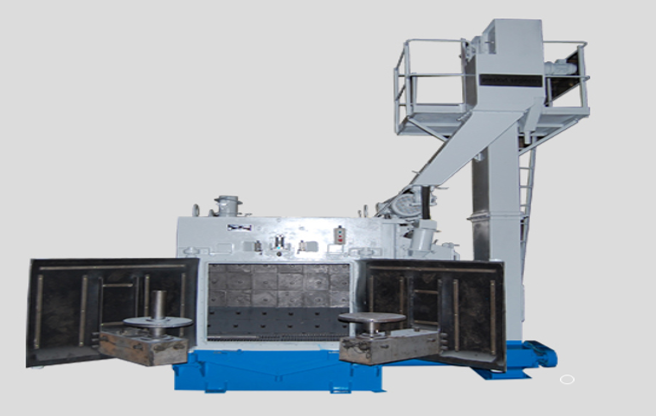

Wheel Peening systems deliver reliable process-safe treatment of work pieces of all geometries, sizes and qualities. The systems are flexible, and so offer long term investment security if process or product Wheel Peening serves to increase the fatigue strength of components subject to high alternating stress.

What are the advantages of Wheel Blasting?

- It has widely superseded other time-consuming and expensive processes.

- It permits the design of light weight and lower cost.

- Indexing table type Shot Peening Machine are specially used to cater the components of different industries

What are the applications of Wheel Peening?

Industries on which Wheel Peening is done include Aerospace Industry, Medical Industry, Automobile & Vehicle Manufacturing Industries. Generally these jobs are Blades, Gears, Engine Pistons, transmission Shafts, Medical Instruments etc.

We do Wheel Peening of

- Leaf Springs

- Gears

- Coil Springs