What are the advantages of Shot Peening?

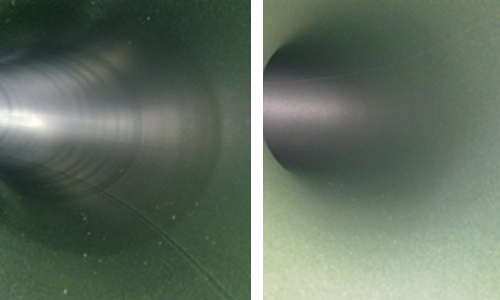

Shot Peening increases resistance to: Fatigue failure, Corrosion fatigue, Hydrogen assisted cracking, Cavitation erosion, Stress corrosion cracking, Galling Fretting.

Shot Peening Helps with: surface texturing, intergranular corrosion resistance, closing of porosity, testing of bond coatings, work hardening, increased strength, and increased durability.

What are the applications of Shot Peening?

Shot Peening when applied on following components increases its service life

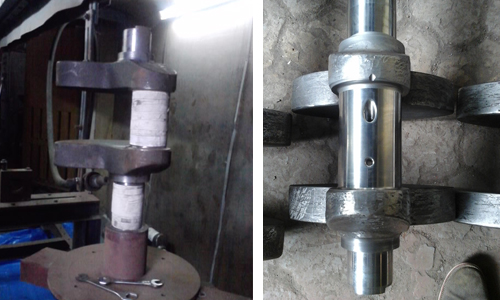

Pins – 400-1900%.

Shafts – 700 %

Helical springs – 3500 %

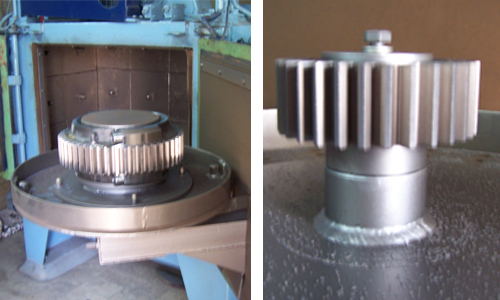

Gears – 30 %

Valves – 700 %

(An overview of shot peening – A Niku Lari IITT, France)

HOW WE CAN HELP YOU?

Why invest valuable time and money in machineries and training when our expertise is available at affordable price.

We have over 10 years of experience shot peening wide range of components like gears, crank shafts, propeller blades and

We follow latest international standard in Shot peening AMS 2430. We have calibrated gages, imported Almen strips and use AMS grade peening media like Steel shots, Ceramic shots, and Glass beads.

Our facility is ISO certified, we use standard procedures and control plans for every unique job. We have regular in house operator training to maintain skill and competency of the shot peening machine operators.