What is Blast Cleaning?

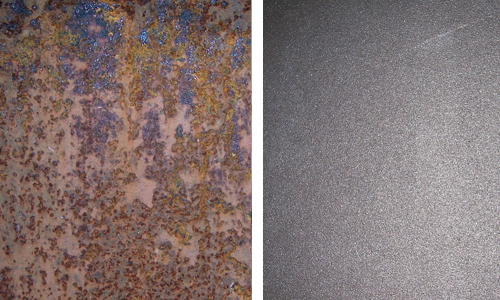

Shot blasting or Grit blasting is process of cleaning metal parts in which steel shots/grits are forced through a jet nozzle using compressed air pressure or through wheel type machine. This creates a fast and effective way of cleaning or preparing surfaces for coating.

Use of abrasive materials like Glass beads, aluminium oxide, garnet etc is also made to clean or texturize non-ferrous metal surface, or decorative items.

More over Blast cleaning process is most efficient and economical in comparison with conventional surface preparation processes namely manual cleaning and acid cleaning.

What are the advantages of Blast Cleaning?

It cleans the surface from rust, scale, paint, dirt, grease, rust etc and exposes parent material.

It imparts uniform surface roughness or anchor profile that leads to increased surface area for better bonding strength with paint or any other coat

It also improves aesthetics of the components by imparting matt finish. Eliminates surface irregularities like welding spatters, scratches, grinding or filing marks

It improves quality of electroplating, painting, powder coating, or rubber lining.

Imparts skid proof property to marble and granite flooring.

What are the applications of Blast Cleaning?

Blasting can be used to clean hardwood, metal, brickwork, concrete or stone. Shot blasting process is carried out on castings, forgings, fabricated parts etc.

However expensive the coating is bound to fail with improper surface preparation. Hence it is mandatory to blast clean the surface prior to painting, powder coating, rubber lining, electro plating or metalizing.

Glass beading removes stains of welding, and scratches of grinding marks on SS fabrication by imparting white colour. It is mainly applied on pharmaceutical machinery, SS pipes and fittings, textile machineries and food industry.

Abrasive blasting is used for wide range of application like preparing surfaces on non-ferrous metals before re-coating or used for engraving on decorative stone or polish soft metals and plastics

How we can help you?

We have wide range of machineries including blast rooms sized 6mtrsX4mtrs to carry out shot/grit blasting of your components

We have dedicated chamber for non ferrous surface to avoid contamination

We have calibrated gages like DFT gage, Surface temperature gage, dry wet thermo hygro meter, Profile gage, holiday tester, Press-o-film etc for quality control

We provide test reports and certificate of conformance with the job

We have used virtually every blasting media on every surface like MS, SS, Brass, Aluminum, Resin, Wood etc.