Shot Blasting on C.I. Casting

Introduction – The images below are of C.I. Castings. Cast iron is a group of iron-carbon alloys. Its usefulness derives from its relatively low melting temperature. Cast iron tends to be brittle, except for malleable cast irons. With its relatively low melting point, good fluidity, cast ability, excellent machinability, resistance to deformation and wear resistance, cast irons have become an engineering material with a wide range of applications and are used in pipes, machines and automotive industry parts, such as cylinder heads, cylinder block, sand gearbox cases. It is resistant to destruction and weakening by oxidation.

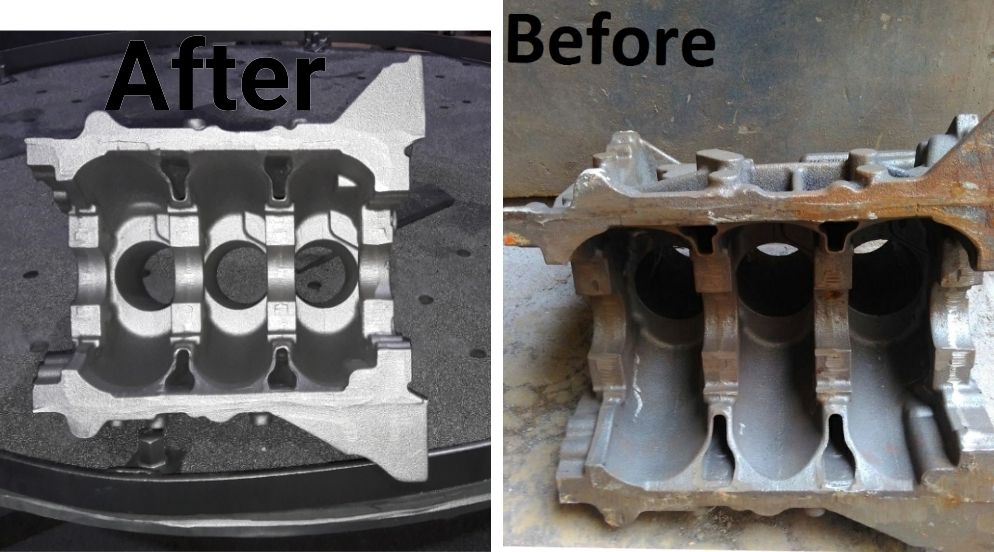

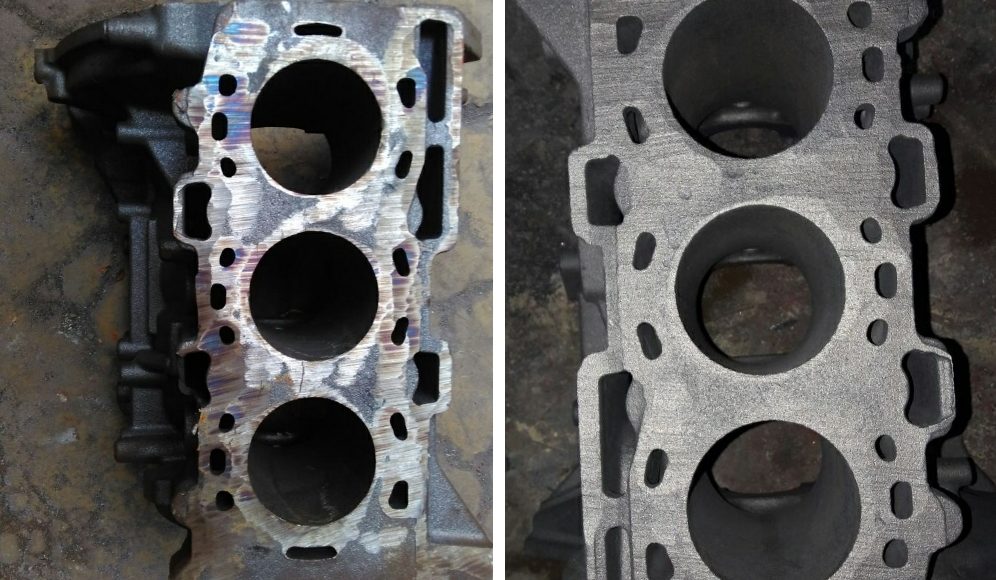

As the casting comes out of the foundry, due to it’s hot surface sand sticks to the surface of the casting. The surface is not uniform and there is rust on the surface of the casting.

So to make the surface sand free, to clean and make the surface rust free and to prepare a uniform surface Shot Blasting process is a must. Shot Blasting process creates a fast & effective way of cleaning or preparing surface for coating.

Requirement –

1) To clean and make the surface sand free

2) To make the surface rust free

3) To create uniformity on surface

Corrective Measures –

Shot Blasting is an effective process on C.I. casting to make the surface sand free, to make the surface rust free & to create uniformity on the surface. It imparts uniform surface roughness or anchor profile that leads to increased surface area for better bonding strength with paint or any other coat.

Result –

After Shot Blasting process the C.I. casting has become sand free, rust free and creation of uniform surface has been done.