Shot Peening

Shot Peening increases resistance to: Fatigue failure, Corrosion fatigue, Hydrogen assisted cracking, Cavitation erosion, Stress corrosion cracking, Galling Fretting.

Shot Peening Helps with: surface texturing, intergranular corrosion resistance, closing of porosity, testing of bond coatings, work hardening, increased strength, and increased durability.

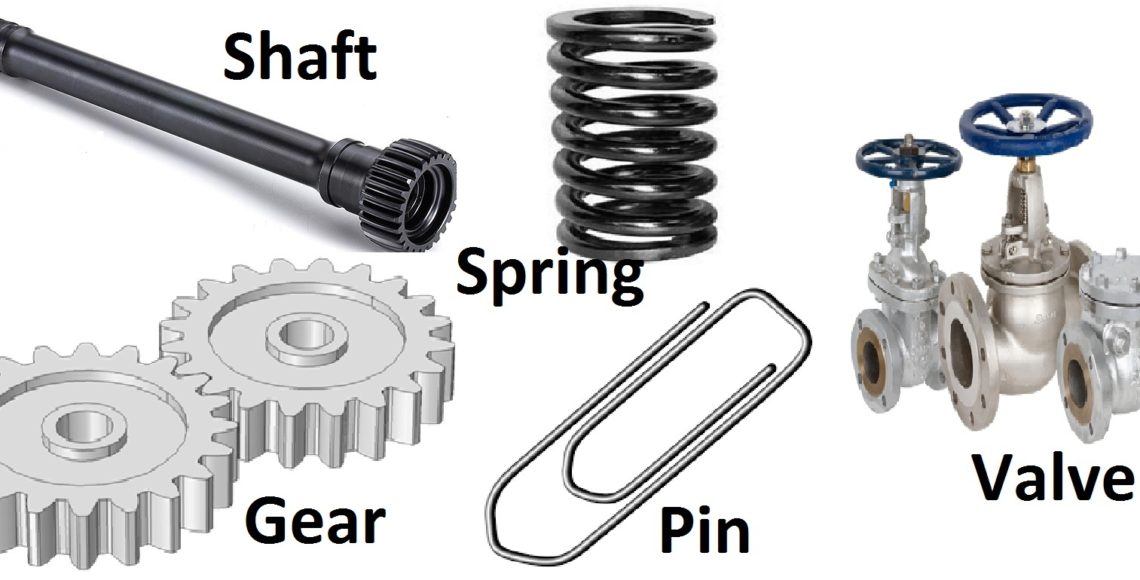

Shot Peening when applied on following components increases its service life

Pins – 400-1900%.

Shafts – 700 %

Helical springs – 3500 %

Gears – 30 %

Valves – 700 %