Aluminum Oxide Blasting on Aluminum Casting

Introduction – The images below are of Aluminum Castings. Aluminum is a chemical element. It is a silvery-white, soft, nonmagnetic, ductile metal. Aluminum is remarkable for its low density and its ability to resist corrosion through the phenomenon of passivation. Aluminum and its alloys are vital to the aerospace industry and important in transportation and building industries. Casting is the original and most widely used method of forming aluminum into products.

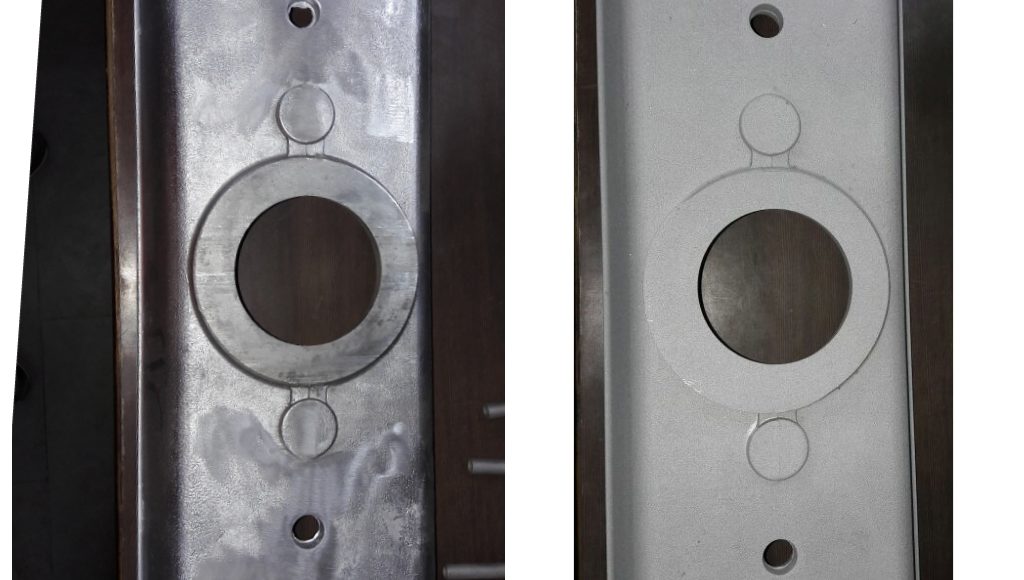

The negative impact on aluminum is that because of corrosion the surface gets black and as the surface is not uniform.

To overcome this negative impact on aluminum, Abrasive Blasting is must. Abrasive Blasting should be done by aluminum oxide plating. The aluminum Oxide in shape of grit. Aluminum oxide blasting is a safe & efficient process for cleaning the black surface and for creation of uniformity on the surface of aluminum casting.

Requirement –

1) Cleaning the black surface

2) Creation of uniformity on the surface

Corrective Measures –

To clean the black surface and to create uniformity on the surface of aluminum casting, aluminum oxide blasting should be done. Use of abrasive materials like aluminum oxide is made to clean or texturize non-ferrous metal surface. Abrasive blasting is also used for preparing surfaces on non-ferrous metals before re-coating.

Result –

The black surface has been cleaned and creation of uniform surface has been done after Abrasive Blasting(Aluminum Oxide Blasting).